Are you also feeling a little overwhelmed by the idea of making the transition to a circular economy? Where do you start? And which way should you go? I asked Jasper Steinhausen, partner at Ouroboros AS, who specialise in generating business by means of circular economy, to share with us a guide to getting started.

If you only remember one thing from this article, it should be this:

When integrating circular economy into your organisation, start and end with your business.

By this I mean that you should start with a problem or a dream someone has, and approach it by means of circular economy. A problem or a dream that is big enough that someone will love that you found a solution to it – and will happily pay for your solution.

This ensures relevance and significantly increases the chances that the solution can – and will – be scaled up. A truly circular business initiative generates both business value and environmental value. In other words, taking your business as your starting point is the key to boosting your environmental results, telling a better story and adding value.

So regardless of why you are interested in circular economy, start and end with your business.

3 steps to going circular

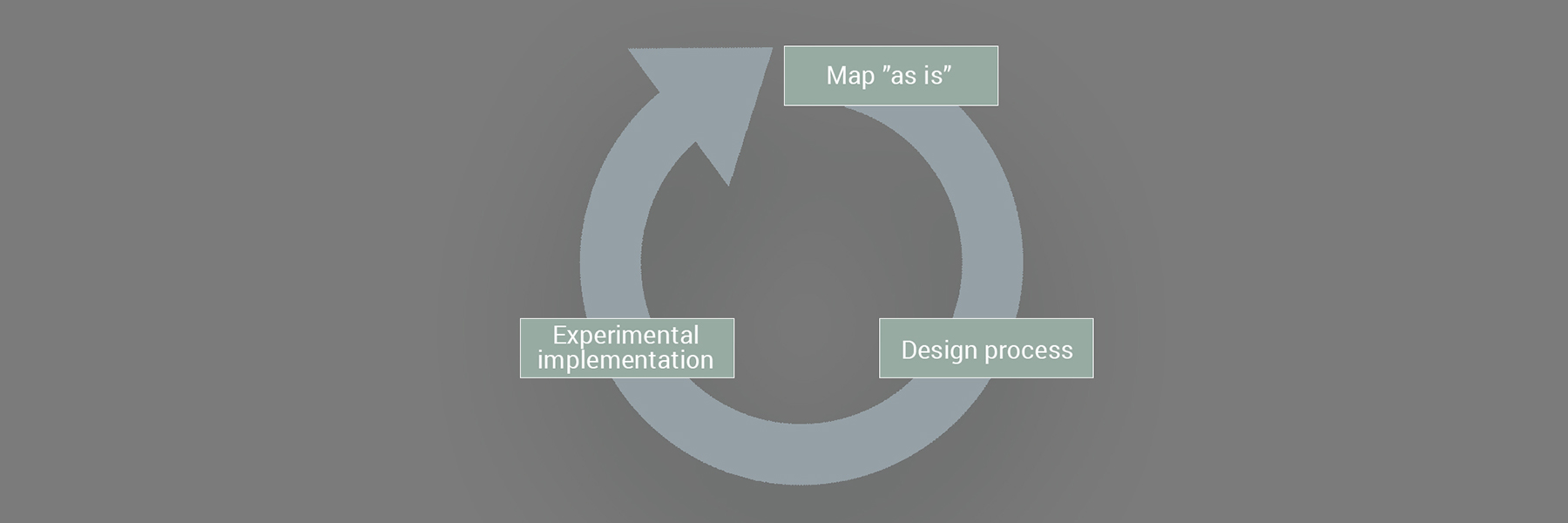

We have designed a simple model that is easy for people to understand, but that contains layers and complexity, so it can be used to develop a circular economy by beginners and experts alike.

A key element of the model is that it is iterative. Working with circular economy is an iterative process, where you continually build on learnings and results. By trying out new things, gathering experience and planning the next step, you can:

- Achieve valuable learning

- Take manageable steps

- Continually calibrate based on the market’s response

The model looks like this, and in the following I will review the three steps:

1. Map the current situation

Follow the flow of resources through your value chain. Identify the different processes and activities, as well as how and where they interact.

Examine the chain as a whole, as well as the individual links in the chain. Pinpoint links and relations to your community, partners, customers and suppliers. It is important to couple this overall level with the circular mindset and its goal not merely to minimise the negative impact, but rather to make a positive contribution. Could your company play a different role? What positive contribution could you make?

This step is about exploring, not making in-depth analyses. It is a process of discovery for the purpose of gaining an overview of core activities, such as resource consumption, production, creation and loss of both the experienced value and the actual value of materials, customer relations, the context in which the customer uses the product and how the product might make life easier/better/cheaper for the customer, distribution, impact, etc. And continually looking at things from a circular perspective.

Try breaking down your circular thinking into these four basic questions:

- What would it take to make more with less?

- What would it take to be able use our resources more than once?

- What would it take to increase the utilisation rate of our product?

- Are there places where we add chemicals that diminish the value of the materials because they can’t be reused? What would it take to avoid this?

There are, of course, many other ways to go about this, and other models you can follow. But what makes our four questions useful, is that they are simple and worded so that everyone can understand them. This makes it possible for people from different professional backgrounds and organisational levels to work together to gain new perspectives on your production.

The result is an overview of how you do things today, the consequences this has and a collection of ideas for where you might choose to implement changes.

2. Defining the result and design process

Business is about results. And strategy is effectively about finding the shortest path to achieving the desired results.

Remember that from a circular economy perspective, a good result is one that generates business value as well as positive environmental impact.

Think of it as doing business with built-in positive environmental impact, rather than as an environmental project with a reasonable ROI. Spend a little extra energy on this phase in order to achieve the necessary clarity about the results you want to achieve and why.

The next step is to design the right process that will produce the desired results.

Remember that circular economy is a much more holistic mindset than most people are used to. It is therefore necessary to get people involved and to co-create across departments, disciplines and organisational levels. It can also be valuable/necessary to involve people from other links in the value chain and in your community. Choose one person with process expertise and a good understanding of circular economy to lead this phase.

Validate assumptions

Chances are, you will find yourselves in places you have never been before. In other words, there are more unknowns than usual, and this places demands on the process.

We have developed a model for leading circular innovation/development processes. The model is based on the following three steps:

- Based on the idea you want to realise, identify the fatal assumptions behind the idea. A fatal assumption, if it cannot be validated, can cause the entire idea to fail. Like the legs on a chair – it will tip over if one of them isn’t there to help hold it up. A fatal assumption might be that the customers want a new feature or are prepared to return a product after they have finished with it. Or that a given material can actually be reused.

Once they are identified, you need to determine the easiest, fastest and cheapest way to validate or invalidate them. - Test your fatal assumptions. If you have assumptions that are linked to the market, then make sure to test them via purchasing scenarios so you get genuine responses about your customers’ willingness to pay. If necessary, make a ”minimum viable product” to use in the test – that is, the simplest possible version.

- Analyse the results of the test and use the knowledge gained to make improvements to the idea. Then, you can repeat the three steps if there are still fatal assumptions that need validation.

Practical experimental implementation

I could also have written here, “build the bridge while you walk on it”. This is actually an extension of the fatal assumption validation exercise.

Because circular solutions are often new, and they may alter relations in your value chain, there are a lot of unknowns. And it is almost impossible to predict what will happen.

I therefore recommend an approach based on action rather than extended studies and analyses. One where you regularly test and evaluate, and then use the learning gained to determine whether to continue or adjust your course.

Several rounds in the model

Many will discover that after completing the model’s three steps, your situation has changed. It can therefore be beneficial to do another round of the model to finish developing the solution.

About Jasper Steinhausen

Jasper is business adviser and co-owner of Ouroboros A/S – a firm specialising in generating business by means of circular economy. They help customers find a way forward – a way to work with circular economy that adds value for their organisation. Ouroboros A/S have more than 25 years of experience with the circular mindset and have worked with companies, organisations, cities and regions.

See more atwww.ouroboros.works